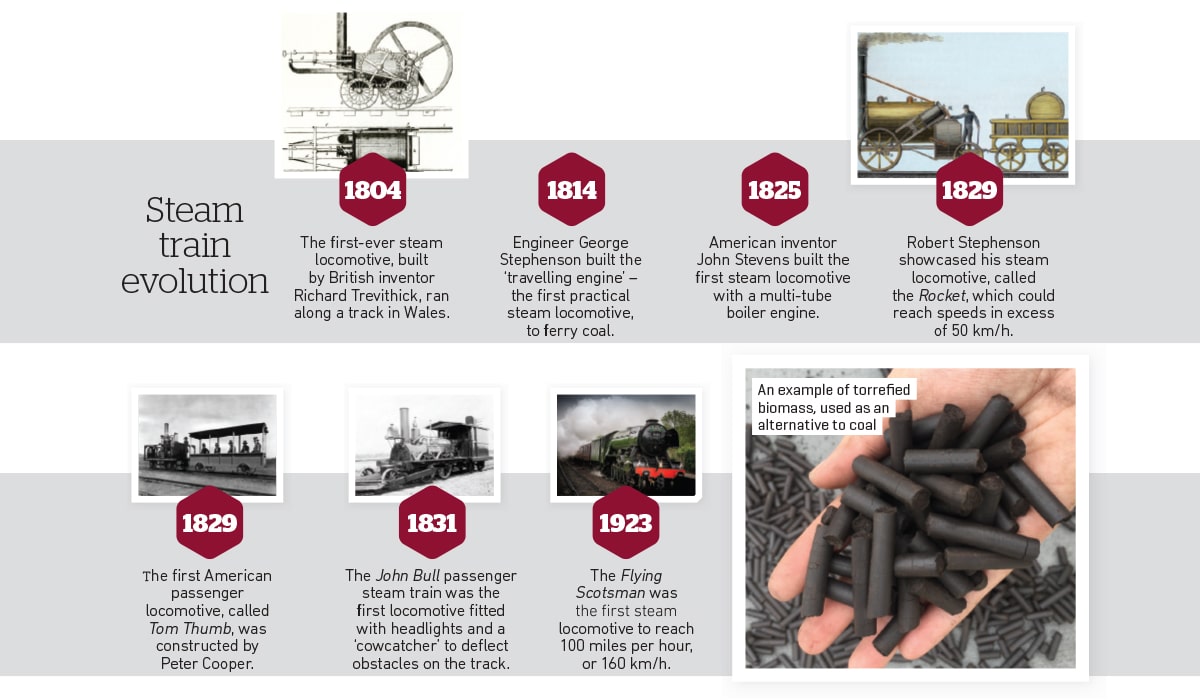

Encapsulated in billowing clouds, steam trains have now been trundling around the world’s railway systems for around 200 years. To propel them along their tracks, steam locomotives have traditionally used the energy released by burning fuel, such as coal, to heat a boiler of water.

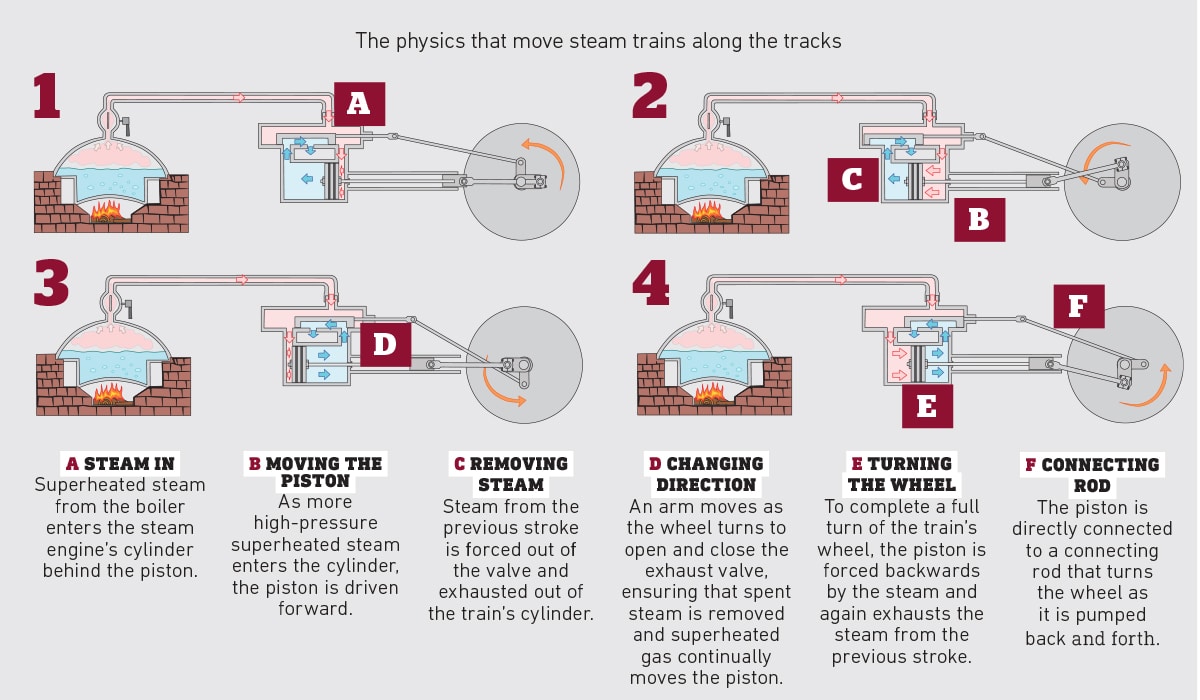

As the water warms up and generates steam, the pressure inside the boiler will increase. Attached to the boiler is a reciprocating piston mechanism that is powered by the high-pressure steam, which causes it to move back and forth and ultimately drive the adjoining train wheel. The steam then finds its way out of the train through a chimney in billowing white-grey clouds of exhaust.

With an external combustion engine, traditional steam trains ran the risk of rogue embers igniting other fuel on the train or causing damage to the tracks below. To mitigate this risk, the first fireless locomotives were introduced to the market in 1882. Like with other steam engines, superheated water was the source of their propulsion, but the water was loaded into the locomotives, preheated and pressurised. This meant that the locomotives could only run for as long as the water stayed hot, or until the water ran out.

Gaining traction

During their heyday, steam locomotives were adapted to carry tonnes of freight and move passengers up mountainsides. However, by the 1930s, coal-fuelled steam trains were in decline, with diesel- and electric-powered trains leading the charge as the modern way to travel. Steam trains haven’t disappeared completely, though, remaining in use around the world for both recreational and practical purposes. While the mechanics of steam locomotives remain similar today as they did during the early 1900s, there have been some upgrades to the way they consume fuel. For example, some locomotives have adopted a Gas Producer Combustion System (GPCS) to enhance fuel efficiency. This system reduces the amount of airflow into the firebox and redirects some of the steam from the engine to increase the efficiency of the coal’s combustion.

In place of the coal piles of traditional steam trains, many modern locomotives are adopting different types of fuel, such as oil or biofuels. German train manufacturer Dampflokomotiv- und Maschinenfabrik (DLM) has developed steam locomotives that have replaced coal with a ‘light oil firing system’ to reduce greenhouse-gas emissions and provide the driver with better control of the train. DLM recently completed the conversion of a traditional 99 787 steam locomotive from coal to this light oil system.

Researchers are also finding new and interesting ways to keep people’s passion for the steam locomotive alive without the environmental cost of burning coal. At the University of Minnesota’s Natural Resource Research Institute (NRRI), scientists have transformed a plant-based material into a carbon-neutral biocoal known as torrefied biomass. The procedure of torrefaction requires plant matter such as wood to be heated up to around 300°C in the absence of oxygen. The resulting blocks of biocoals release significantly less carbon dioxide than traditional coal but can still burn at a 96 per cent thermal efficiency.

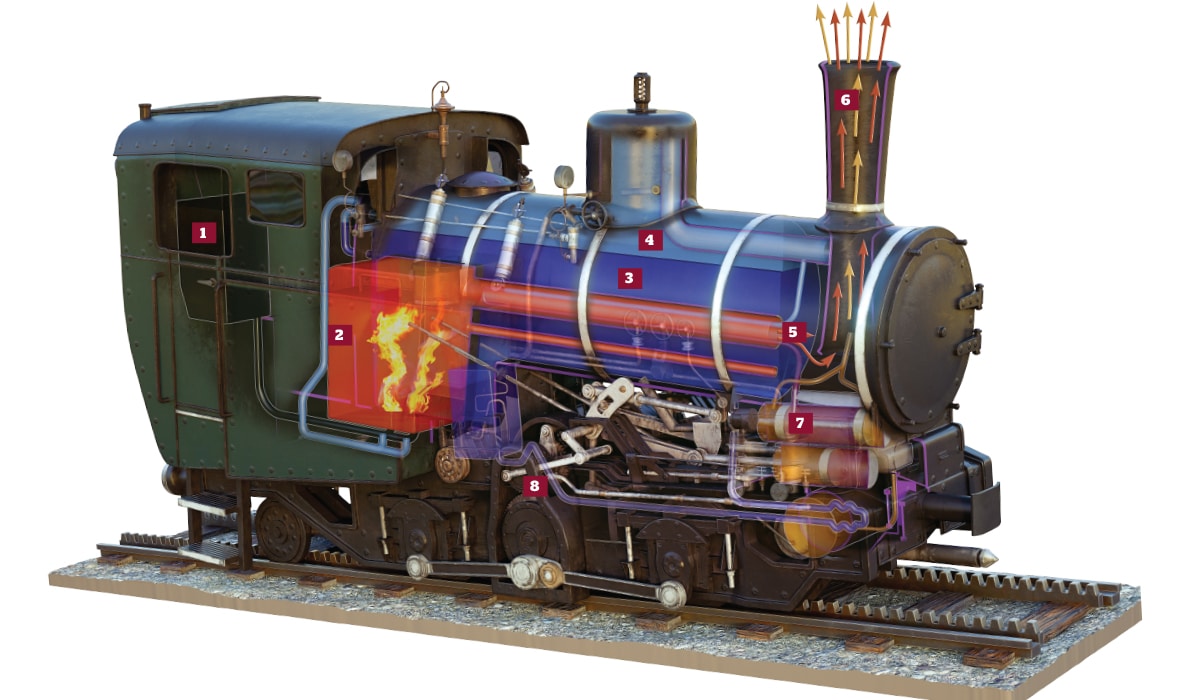

The science of steam

How modern steam trains turn boiling water into forward motion

1. Fuel

A light crude-oil reservoir feeds fuel into the firebox to be burned.

2. Firebox

Oil is funnelled into the firebox and ignited to generate enough heat to boil the surrounding water-filled boiler.

3. Heating water

Hot air, produced by the combustion of oil, flows through pipes surrounded by water.

4. Creating steam

Water housed in a tank is heated to more than 200°C to generate steam.

5. Superheated steam

Steam passes through a series of pipes close to the firebox, reaching around 420°C

6. Chimney steam

The steam exhaust and excess heat are vented and released into the atmosphere via the chimney.

7. Enter the engine

The superheated steam enters the train’s piston engine to drive the crankshaft.

8. Turning the wheels

The driving rod connected to the engine drives the train’s wheels along the track.

9. Steam brakes

Steam produced in the boiler is also used in the train’s braking system.

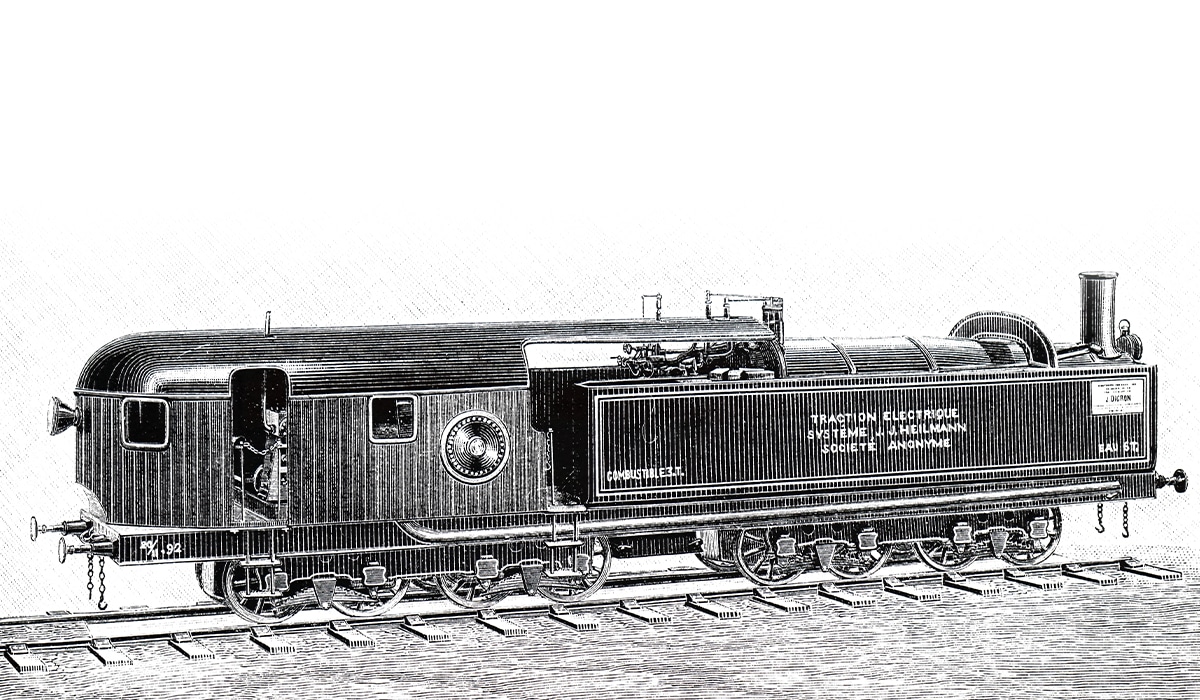

Heilmann’s Steam-electric locomotive

With an ambition to combine steam propulsion with electrical power, French rail pioneer Jean-Jacques Heilmann patented the first locomotive that used a steam engine to generate electricity in 1890. The original Heilmann locomotive, a 16.3-metre-long train, was driven by a two-cylinder steam engine that turned a 400-kilowatt generator for electrical propulsion. A completed locomotive was showcased in 1893 on a test run in Paris. The following year, in a test run carrying 250 guests on the railway network in Compiègne, it reached a top speed of around 108 km/h. However, owing to the complexity and expense of building trains that used steam and electricity, Heilmann’s locomotives weren’t further developed or constructed.

By Nicholas Forder

Images: Alamy/Getty/Shutterstock/Illustration