Denislav Marinov, founder of Amnova, is on a mission to make 3D printing technologies more accessible across South Africa.

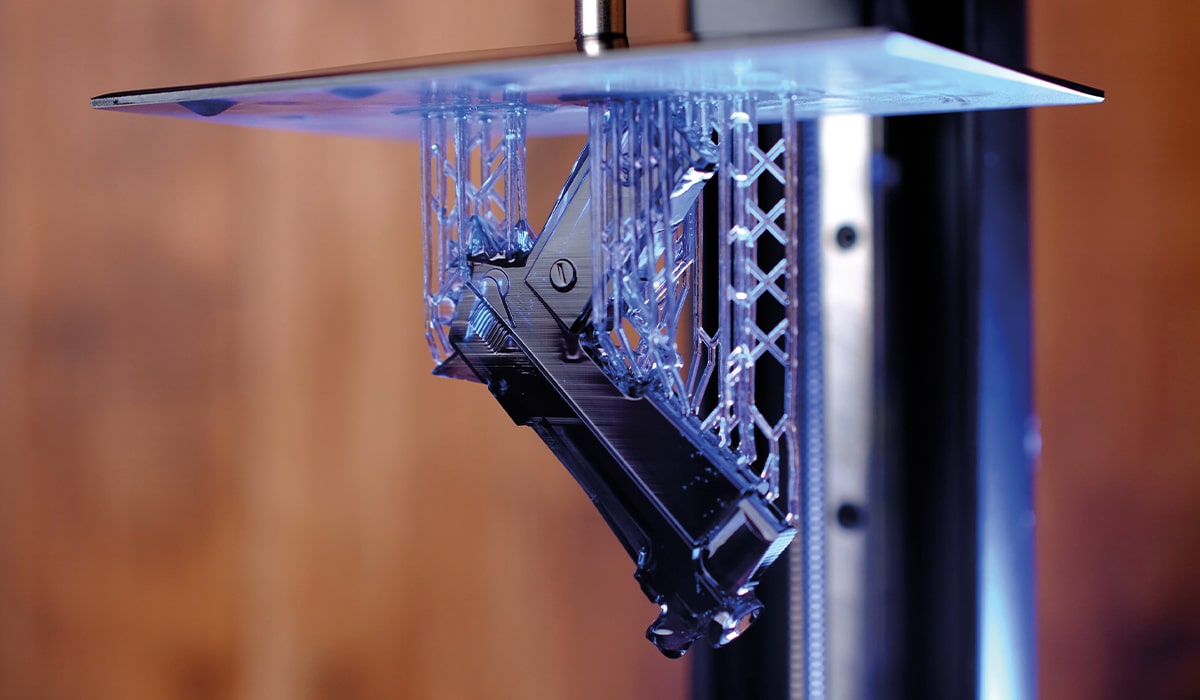

The process of 3D printing, also known as additive manufacturing, builds three-dimensional objects layer by layer. Lately, this relatively new technology is becoming extremely popular, and a lot more accessible, allowing for the creation of anything from home decor to medical devices. We had the opportunity to speak with Denislav Marinov, the founder of Amnova – a start-up at the forefront of developing sustainable 3D printing technologies – to learn more about the process and how to create your own 3D printed piece.

@kuyamagik How a 3D printer works #3dprint #3dprinted #3dprinting #tikoku #edutokph #learnontiktok #howthingswork #tutorial ♬ How a 3D printer works – Kuya Magik 🪄

“I started the journey into 3D printing in high school,” says Denislav. “I received a printing kit for my 14th birthday, and I was instantly mesmerised by the technology that would allow you to take an image and bring it to life. In a South African context, where there’s not much access to manufacturing, I decided to investigate it further, starting with creating gifts for my family to gaining my first commercial client in my last year of high school.” Early on, Denislav recognised 3D printing’s cross-functional value. From there, he began to work towards his start-up, Amnova, testing large format additive manufacturing (AM) systems. During this period, he realised there was a desperate need for these systems and services in Africa. “3D printing is a massive enabler,” he says. “Africa accounts for less than 2% of the global manufacturing output because there’s a lack of modern manufacturing technologies locally. I believe 3D printing will enable the next generation of local manufacturing, leapfrogging established industries around the world by leveraging this new technology.”

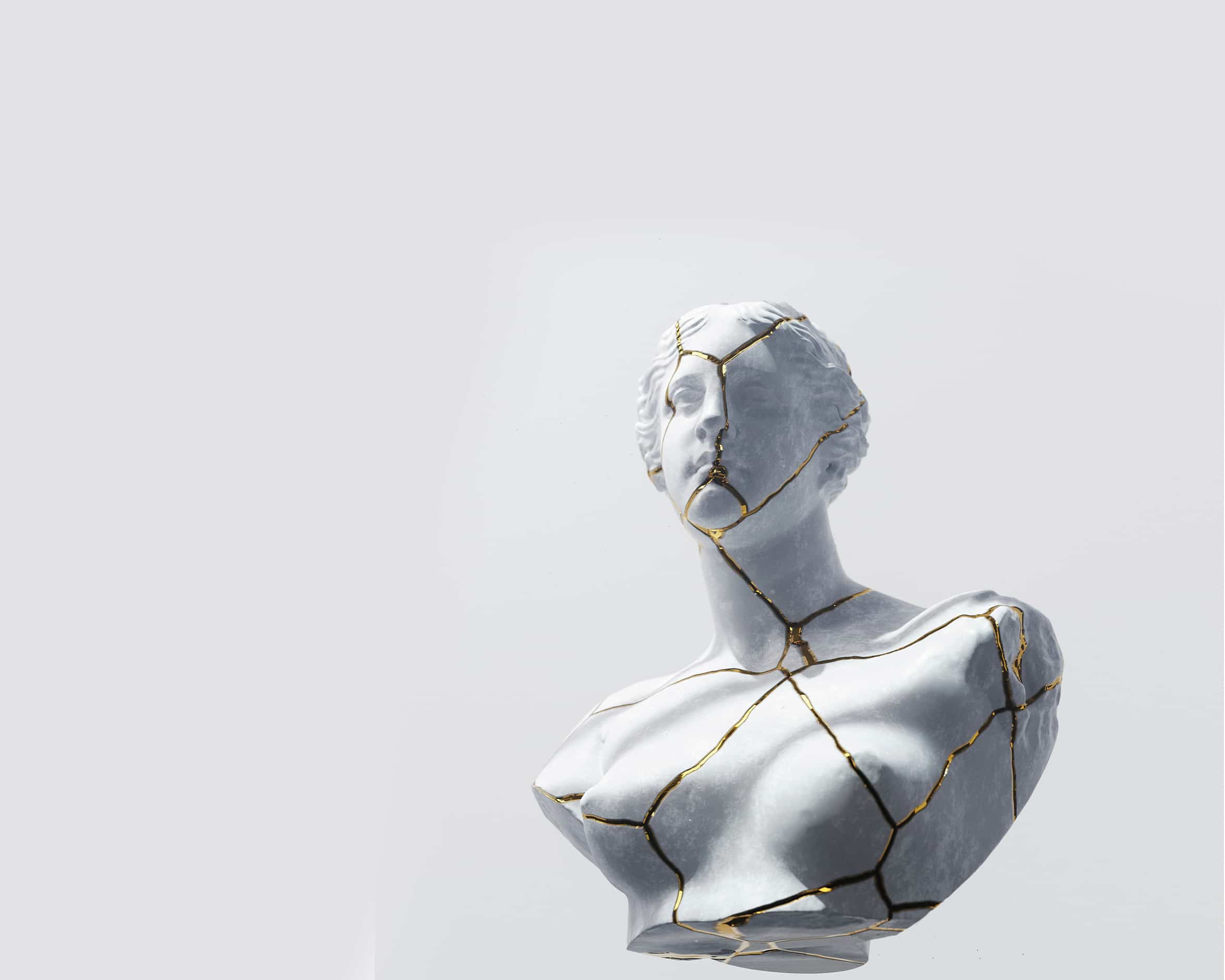

This shift will see 3D printing being used in prototyping and in the production of in-use parts, particularly in small- to medium-volume production, so products wouldn’t need to be made in the millions. Nowadays, the materials used in 3D printing are so advanced, allowing you to produce parts even stronger than a traditional process. However, one of the most alluring elements of 3D printing is that it is industry agnostic – something that can be used in any market or solution without being limited. This has paved the way for 3D printing to be extremely useful in the design world – extending to furniture, interior design and decor. “3D printing has found an amazing application in the interior space, including lampshades, façades, cladding, and furniture,” says Denislav.

“Amnova is currently exploring furniture, particularly using recycled plastic bottles to create sustainable pieces.” Ultimately, 3D printing removes design constraints and provides the freedom to design parts of arbitrary complexity. We are seeing a wave of merging 3D printing with existing manufacturing – like wooden legs with 3D printed brackets to connect everything – to create organic and complex shapes that can be produced on demand. There are plenty of options when creating products within the design world, especially with the materials that can be used. “You can always use traditional 3D printing materials such as polymers and PLA, a non-petroleum-based plastic made from corn starch, and more industrial materials like ABS, which is typically what plastic furniture is made from,” adds Denislav.

“We are currently also experimenting with ceramics and recycled water bottles to produce furniture and interior pieces.” Even though plastic is traditionally weaker than wood, 3D printing has come a long way and with complex design geometries, you can compensate for reduced material properties. The process involves creating an organic shape that distributes the force more evenly, achieving stronger parts than most processes. But, what is the process?

“To bring an idea to life, there are several steps: First, the idea, whether it’s stemmed from inspiration or if you’re experiencing a problem and are thinking of ways to solve it. The next step is to get those ideas on paper. Then comes a feasibility check before the process starts,” explains Denislav. A common misconception is that you need to have access to large-scale manufacturing capacity to get your ideas out there, but with service providers like Amnova, that step becomes a lot more accessible. “After developing a refined version of your design, it allows you to print in a matter of hours, going through several prototypes, ideas as well as iterations that can be tested and tweaked before producing a few units for customer feedback.”

3D printing is actively disrupting and revolutionising the design world. Leveraging 3D printing allows us to create and bring ideas to life in several different ways, from rapid prototyping to bespoke pieces. As access to 3D technology increases, artists and businesses alike can explore new dimensions of innovation, transforming the way we approach design and manufacturing, and turning concepts into tangible reality.

By Shai Rama

Photography: Pexels, Unsplash, Supllied